All steam boilers and refillable LPG gas tanks operated by society members in a public place and/or at all society events are required to have a valid test certificate. For their own safety, and that of their family, friends and neighbours, members are advised also to have them tested before operating them in private at home. To provide for this requirement the society runs a free boiler and LPG tank testing service for members in accordance with procedures laid down by the Northern Association of Model Engineers (NAME).

Note that only boilers and gas tanks in the ownership of members of the society can be tested – we cannot carry out tests for non-members.

The test procedures are defined in three test code documents which may be found on the NAME website at http://nameng.org.uk/index.

The three documents are: The Boiler Test Code 2018, Volume 1 – Boilers of 3 bar litres to 1100 bar litres; The boiler Test Code 2018, Volume 2 - Boilers under 3 bar litres; The boiler Test Code 2018, Volume 3 – LPG tanks under 250ml. In simple terms the boiler test procedures are as follows: New boilers are subject to a hydraulic “shell test” at twice working pressure to test structural integrity and for any leaks from welded or soldered joints.

This shell test is carried out before steam fittings are mounted on the boiler and the certificate is valid for the life of the boiler unless it is subjected to significant modification or repair. After the shell test the steam fittings (clack valves, water gauge glass, etc) are mounted and the boiler is then subjected to a hydraulic “repeat test” at 1.5 times working pressure to check for security of fittings and for significant leaks. For copper boilers the repeat hydraulic test certificate is valid for 4 years from the date of test. For steel boilers the repeat hydraulic test certificate is valid for 4 years from the first shell test and for 2 years thereafter.

Subject to passing both hydraulic tests the boiler may then be steam tested to check for the following:

- Safety valves blow off such that boiler pressure cannot exceed working pressure plus 10%.

- Pressure gauge reads correctly and is marked with a red dot or line at the working pressure.

- There are at least two independent means of feeding water into the boiler at working pressure (e.g. hand pump, axle pump, injector).

- Water level gauge glass operates correctly with visible water level.

- No significant leaks from steam fittings (There is a variation from this steam test procedure for small boilers under 3 bar litres which may lack some steam fittings and/or means of boiler water feed). The steam test certificate is valid for 12 months.

- Refillable gas tanks for Butane or Butane/Propane mix are also required to be tested but are limited to no more than 250ml capacity.

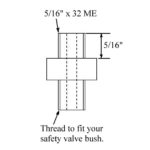

In simple terms the test requirement is a hydraulic test at 400psi to check the structural integrity of the tank followed by a “safeguard” test to check for any leaks when filled with gas. The hydraulic and safeguard test certificates are valid for the life of the tank but there is also a requirement for “safety checks” at intervals of no more than 5 years thereafter. The safety check is basically a test to ensure no gas is leaking from the tank and is recorded in the tank’s documentation. It appears that commercially made LPG tanks with the manufacturers’ original hydraulic test certificate only require the 5 yearly safety checks unless subsequently modified or repaired. It is the boiler or tank owners’ responsibility to prepare the item for testing by the society’s appointed boiler inspectors.For hydraulic tests they should supply a fitting for connecting the society’s test equipment as shown in the sketch below.

That fitting is placed at the highest convenient position on the boiler – usually a safety valve bush or the top of the dome.

For the steam test the owner should supply everything required to fire the boiler including steam raising blower, coal/gas, wood/charcoal to start the fire, shovel, etc. In the absence of these items the boiler inspectors are entitled to refuse to carry out the test but may, by prior arrangement, agree to help members by trying to use their own existing items. They cannot guarantee to have suitable fittings/items however.

Steam tests on railway locomotives are carried out on a rolling road which the boiler inspectors can normally supply for 3.5” gauge (up to 6 coupled wheels) and 5” gauge (up to 10 coupled wheels).