Tonight is the EGM to decide next year's subs etc and as our Secretary is away I shall run it and after a coordinating chat with our Chairman the bell was rung at 19:30 hrs.

Mike first welcomed new member Ian. He then announced that we were going to exhibit the Yellow train and offer rides in the Galleria on 6 th. December along with the De-Haviland model railway club. He asked for some club members to join him, the drivers were already found, but some support to advertise the club and help with setting up would be good.

Then the EGM. I was standing in for Guy and said the committee saw no reason to raise the subs or hall donation for next year and this was agreed by all. The other point was that due to the timing of accounts submissions now the society is a charity the AGM will be moved from April to November from 2026 onwards.

This ends the EGM.

I then said what we have planned for the Christmas evening and hoped all would be coming. There would be a raffle so please bring in items for the raffle and tickets would be sold early in the evening. This also off-sets the free evening income. Mike Grossmith will have a Christmas quiz for us. We shall also have some short talks from members.

Expect an introduction to the Ephraim project from Tony Ashgrove, Baz has an unpronounceable ‘thing’ that works from his lathe! Our Chairman has a totally useless box and can show us the construction there of. If time allows Jim has an interesting group of talks which were actually courses on Renault cars which he was involved with. This may well be expanded for next year. The tea break will include hot extras as usual. If members would like particular subjects featured, I will see what can be done.

I then introduced Jack Wills who was the speaker for the evening. The subject being 3D printing.

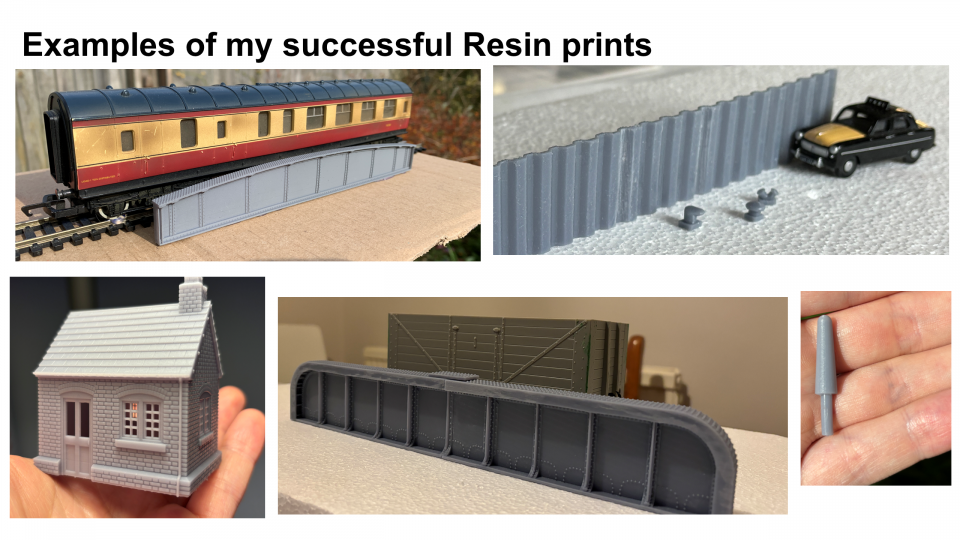

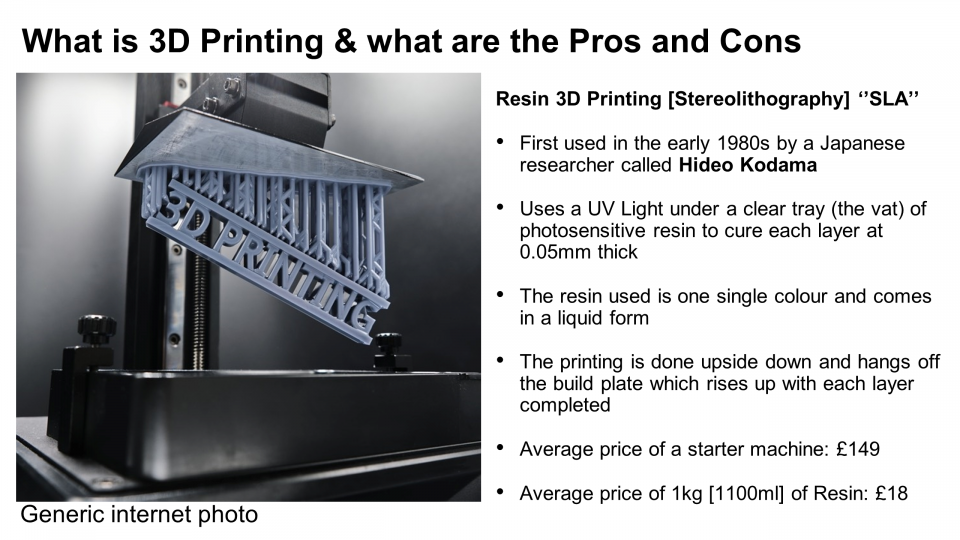

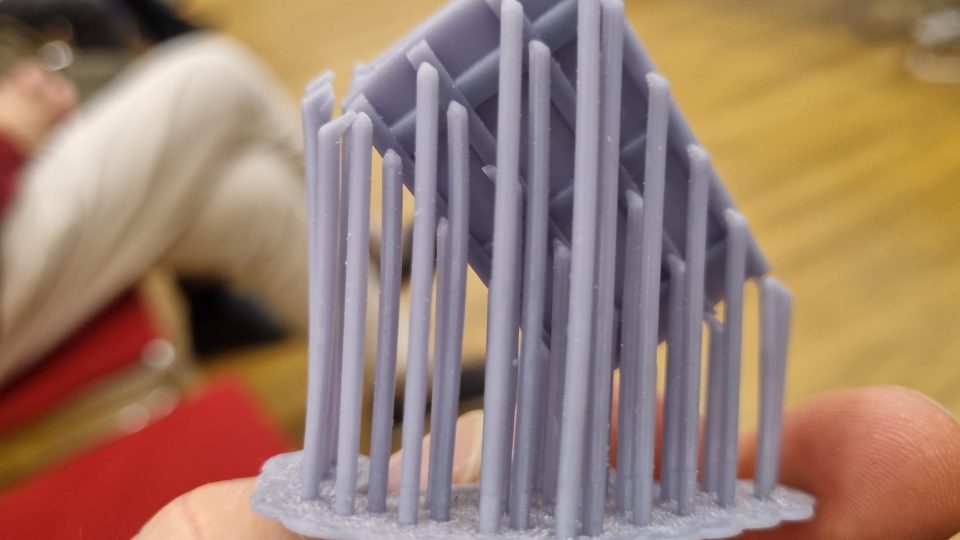

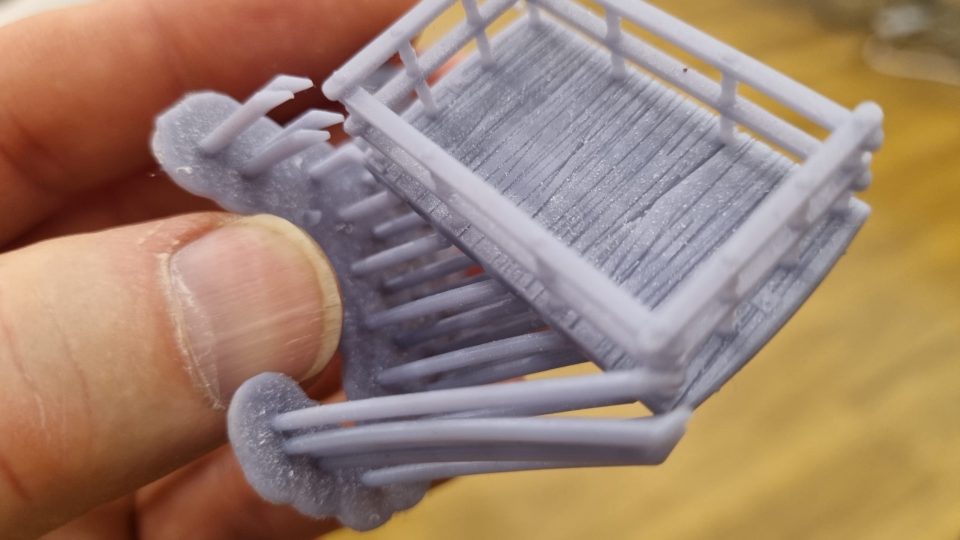

Jack told us about his work in the Covent Garden Opera House as a senior lighting operator and the touring to different parts of the world. Then onto the subject of the evening which was his hobby and a source of income. Jack showed us what he would be talking about and said we could ask questions any time. Jack brought along various things he had made including the failures. Then he showed us a resin printed item and the way it had been done on the slant to get maximum size with in the printing space.

We had a slide show of the equipment he used and diagrams of the way items were printed. The first was how to produce bespoke items in resin. These were formed up-side down and Jack took us through the process with temperatures and resin and running and capital costs. The resin as it hardened needed support as it ascended from the resin and this also had to be included mainly by trial and error and experience. Jack showed us some of his failures and explained why it had happened.

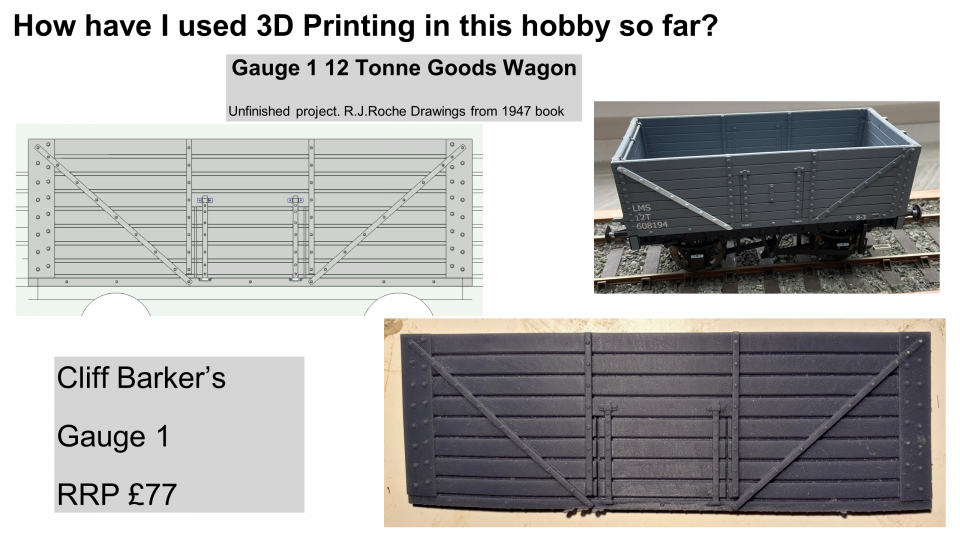

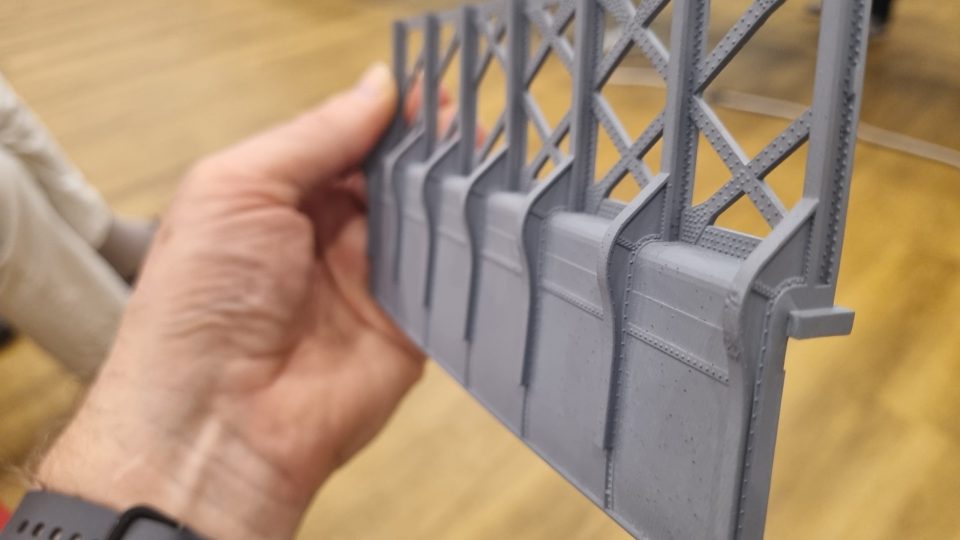

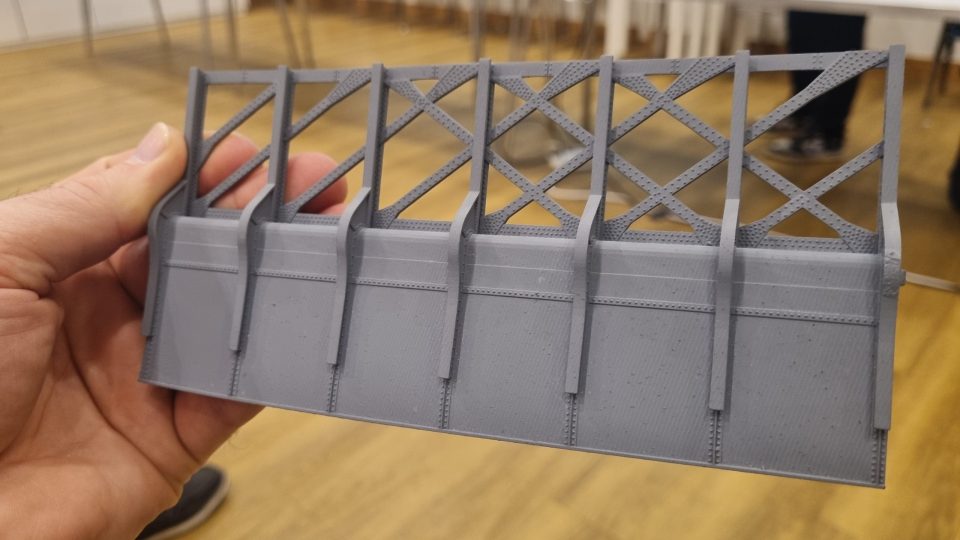

Jack was making things for his hobby of model railways and when he was satisfied with what he had made he offered the item for sale. Developing a small business in Model railway items mainly 45mm track narrow gauge railways. There was a constant flow of questions from club members, and I was surprised how many members had or were contemplating buying 3D printers. Jack went on to explain how items could be glued together and said that he used Halfords acrylic primer and paints, which seems to work well.

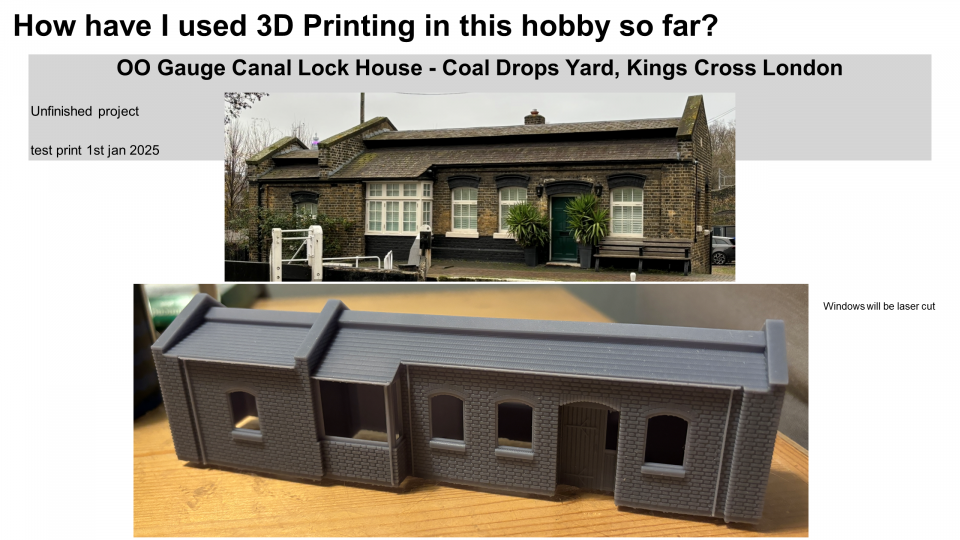

Jack went on to talk about the more common (to me anyway) printer that had a coil feed of plastic which was moved mechanically to deposit thin layers of plastic to form structures using a computer program. Jack said the process of producing a computer file of a building etc. was quite easy. He would see the prototype and photograph it, people in the picture gave dimensions and scale. He worked in several model railway gauges but the finished article had to be of a size the printer could deal with.

Then he made a drawing, if it was a symmetrical bridge then only half needed drawing as the other half could then be mirrored across. The drawing on his computer was then entered into a series of programmes that would eventually come up with the number of slices or passes needed to make it. From then on the scale be it OO or O or G1 could be decided and the testing of the item could be refined to a final form. The finished item was then subjected to UV light to harden.

We broke for tea and Jack left his exhibits out for inspection. Jack and Neil had our drinks waiting for us with biscuits. I had to ring the bell several times to get the meeting going again.

We had an unexpected visitor, Freddie, who we had last seen a year ago and now returned after doing his GCSE's as he had seen our 3D evening advertised. He took centre stage and talked about his involvement with the subject. He was a mine of information on the equipment and recommended particular products and also discussed whether their s/w had reached the limits of updating. Also comparing resin and coil printing and another process which was mainly three letter acronyms and clearly meant something to members in the know. These things have now gone beyond my ‘pay grade’!

Both of our speakers were given an appreciative round of applause. I had final chats with them both and said how much we had enjoyed their presentations. Jack’s work is available on eBay, Freddie is just interested in the printing of solid objects. He was accompanied by his grandfather or ‘chauffeur’ as he later explained.

Our evening was a response to a committee request for the technology to be featured in our evening talks, and I hope understanding was achieved for this surprisingly well-established industry. I suppose much research is going into drone production because of the conflict in Ukraine and the sudden use of very cheap technology that can be used in warfare.

Our thanks go out to club members who furnished the evening with chairs and tables and cleared up at the end, what would we do without you!

Regards to all.

Roy Verden

13th Nov 2025