The May club evening was again an interesting and informative one a trip first through Router cutting and then laser cutting and constructing your own equipment.

However, first our Chairman brought us up to date with the PP situation. We have been out-bid and rather than get into a competition decided to withdraw our interest in the purchase of the land. In talking to our current landlord he expressed the interest we have in renting the area as before. We await results.

We are going to Brambleton on Saturday p.m. and those interested were welcome to attend. Our speaker, David Batchelor then took over for the rest of the evening.

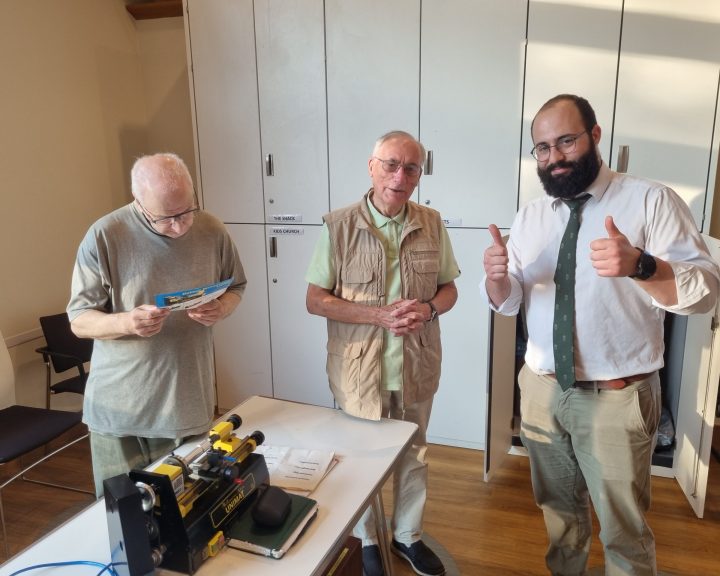

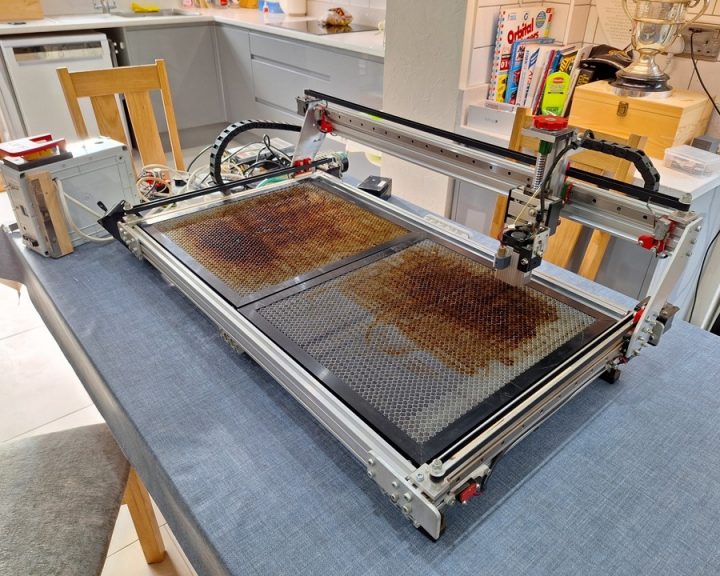

Dave said he got involved helping a friend construct a router cutter and there were enough parts left over, that he managed to construct one for himself. This had to be a strongly made unit as there were considerable forces involved cutting through the wood. He was then intrigued by a 'man cave' engraving done on a laser cutter, this led on to constructing a laser cutter of much lighter build as there were no opposing forces involved. First with a diode laser and then a CO2 laser unit.

Dave explained the setting up of the laser for cutting where the light has to be focussed carefully on the wood surface and setting the correct amount of power to cut through the wood.

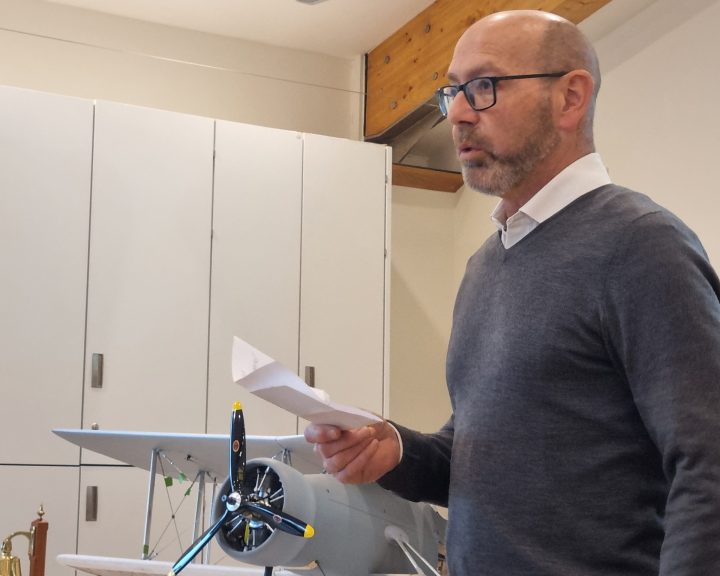

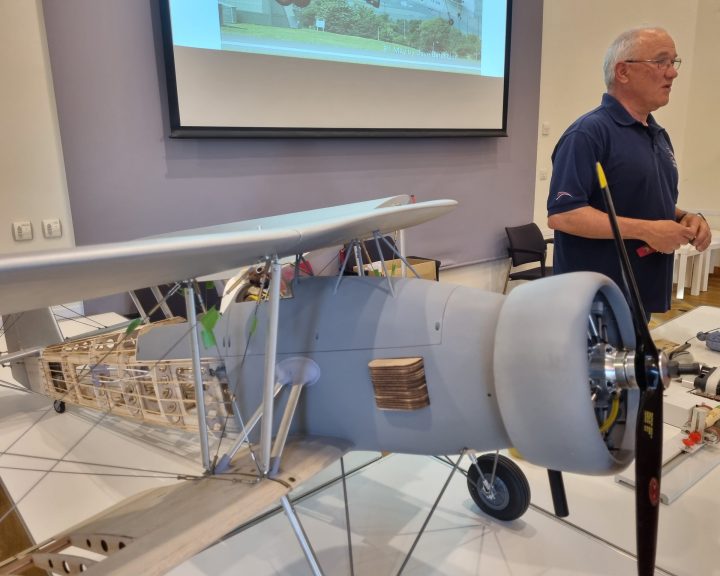

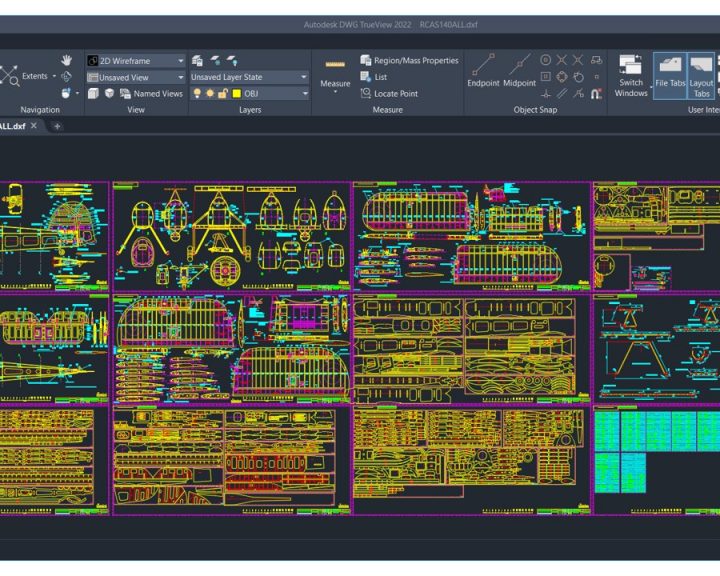

Dave's first DIY machines worked and then he extended the size but eventually bought his own and this was used in the construction of the 7 foot span Fairey Swordfish aircraft he had brought along. Dave showed how simple construction or drawing was done on a laptop and downloaded onto the laser cutter. We saw several videos specially made to illustrate the various procedures he was talking about.

It was turning out to be a tour de force on laser cutting including a device that could rotate an object under the laser in place of the X axis and engrave letters on a curved surface. The CO2 laser was a powerful unit that needed a high voltage to operate it. 16000 volts would just engrave or do light cuts but when running at 26000 volts it would cut through thicker wood easily and quickly. All the laser cutters burnt through the wood leaving blackened surfaces which created smoke and an integral part of the cutter was to blow smoke away from the cutting area as the smoke could obscure the laser beam and the area to be cut.

The whole time Dave was answering questions or confirming he would come to the subject later. We also were shown live drawing and moving of figures to be cut and how the unit draws around the items to be cut to make sure they are contained in the surface area.

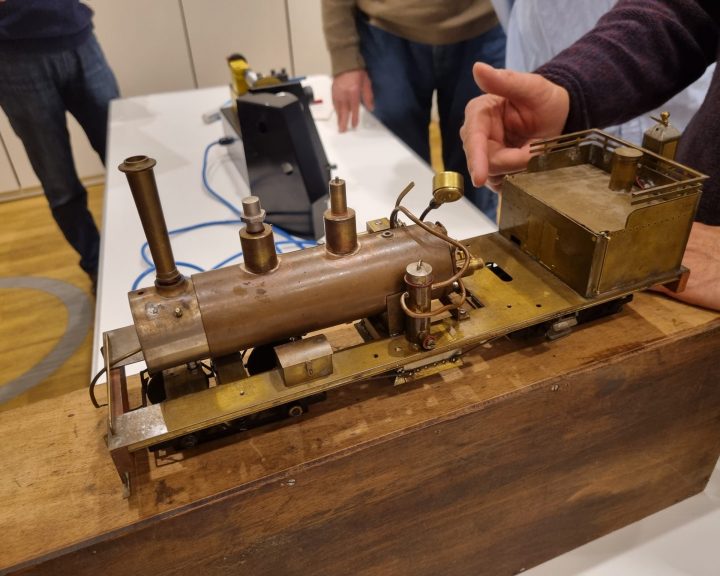

We had a tea break and there were several items of interest on the tables at the back brought in by members including the part-built steam loco and the usual collection of magazines.

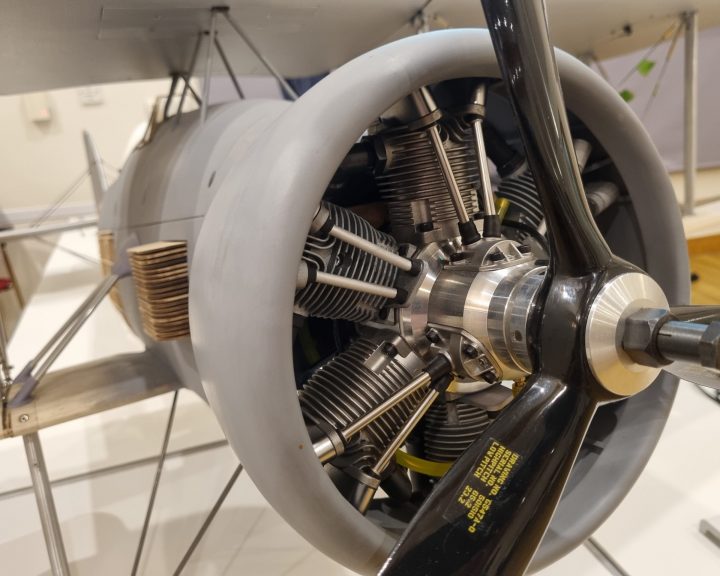

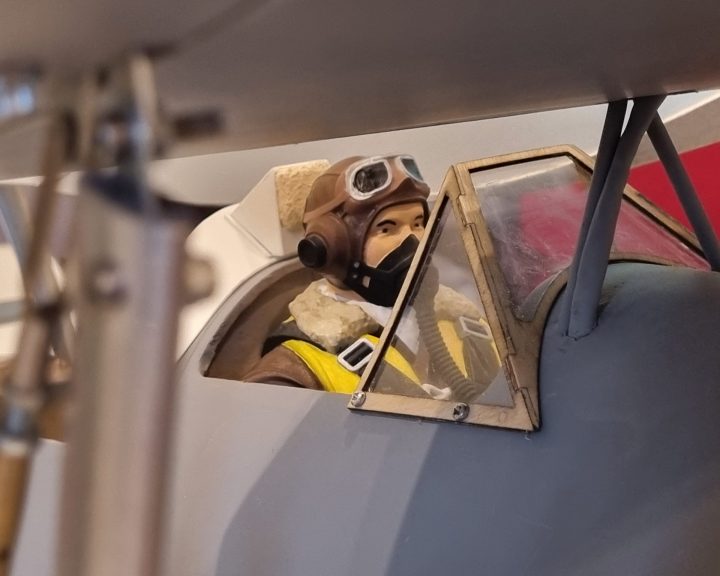

Then back to learn how Dave got interested in the biplane he had brought with him. Both his previous model of the Sea Vixen and the Swordfish were on display at Yeovilton seaborn aircraft museum. Several visits there enabled detailed viewing and close inspection. The Swordfish is famous for its part in the eventual sinking of the Kreigs Marine Bismark. Although the Swordfish was obsolete even before hostilities started its job was to deliver a torpedo across the sea with little expectation of enemy fighters to interfere. The Swordfish also carried airborne radar, most unusual for a biplane. The Kreigs Marine did not have any aircraft carriers as was evident in the Pacific war, so any attack would only come from the target. Many of the aircraft were shot down and you realise how brave the aircrew were to attack such a well-armed and daunting target as a battleship of 40 odd thousand tons!

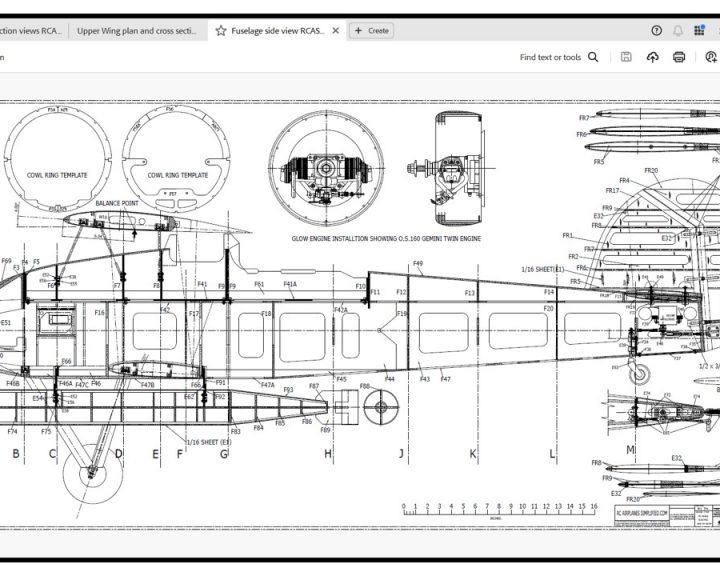

The Swordfish plans were available from Canada at the right scale of 1 : 6. However, using the pdf files was a problem and eventually Dave obtained the originals and even then had to correct the errors and not so obvious problems. For instance, lines having almost invisible overlaps that were sensed by the s/w and treated as open objects. After correcting many of the drawings the parts needed were cut out and assembled.

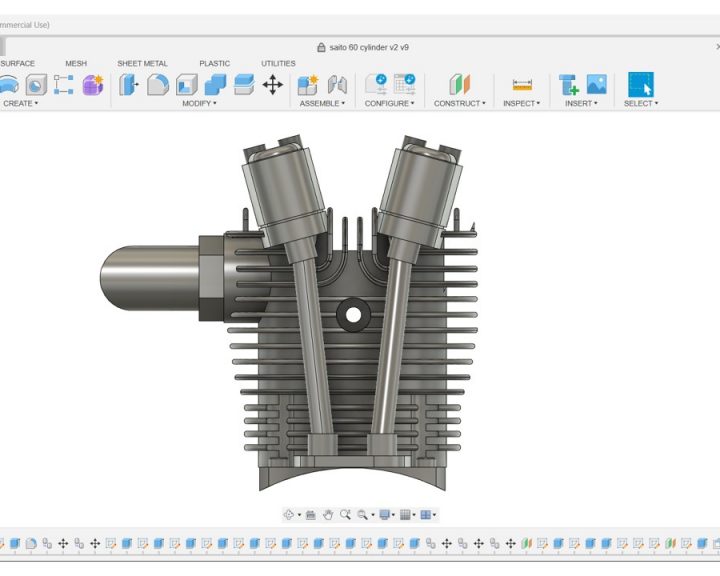

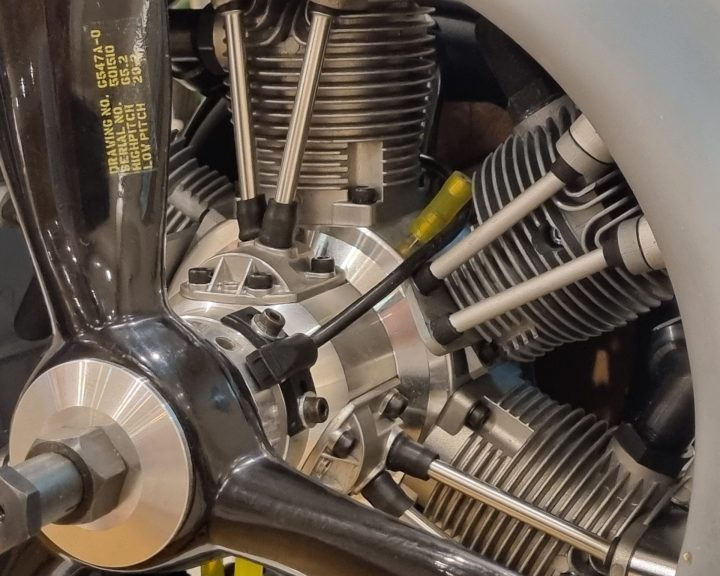

Covering the airframe with the heat shrink material was an expensive exercise as well using materials also used in full size but the colour was just right. The proposed engine for flying is a 3 cylinder one and another exercise was to produce 3 more cylinder heads to fit between the working ones so as to give some indication of the full size engine.

This used resin ‘printing’ which differs from 3D printing as the item is processed by a light which hardens the resin into the required shape, but produces a smooth surface. The final piece is cleaned of sprue and then re-processed to harden it and then painted. The results look very nice. Dave reckoned the spare cylinders helped with the air cooling of the working ones.

Another observation of the full size aircraft was the position of the wheels which look a bit skewed and so the under carriage was altered to show this in the model. Wings and struts were beautifully executed and the wing structure correctly stressed for flying and of course for support when on the ground.

The model plans called for 3 servos to be mounted in the tail area to work the elevators, two in parallel, and the third one the tail fin. This would put a lot of weight in the aft part of the aircraft and would need a considerable balancing weight in front of the wings. The c of g of the aircraft has to coincide with the lifting force of the wings.

The prototype had wire operating the rear surfaces and so Dave decided to follow suit putting the servos in the fuselage just behind the wings and using wire connections as originally designed.

As yet incomplete with some of the airframe needing to be covered Dave reckoned it would be flying this year and we have been promised video of the event. There was so much to see and understand that our usual time constraints were ignored. Dave received a very warm round of applause and we started clearing up let us just say 'a little later than usual'.

Thank you to all those that made the evening work including the refreshments and the setting out of tables and chairs and subsequent clearing up. We 'discretely' left quietly, I hope, having had another interesting evening.

Next time we should be over at the PP so bring your trains, all scales, and anything else of interest but do not forget to bring a comfy chair to sit on. All this weather permitting.

Should it rain then we shall be at the Christchuch Centre, the PP evening being postponed until July, we look forward to seeing all the models you have finished or are currently working on. The evening is yours, the entertainment is your models and enjoying fellow members ones and company as well.

My regards to all and look forward to next time.

Roy Verden. 12th May 2024