October Club Evening.

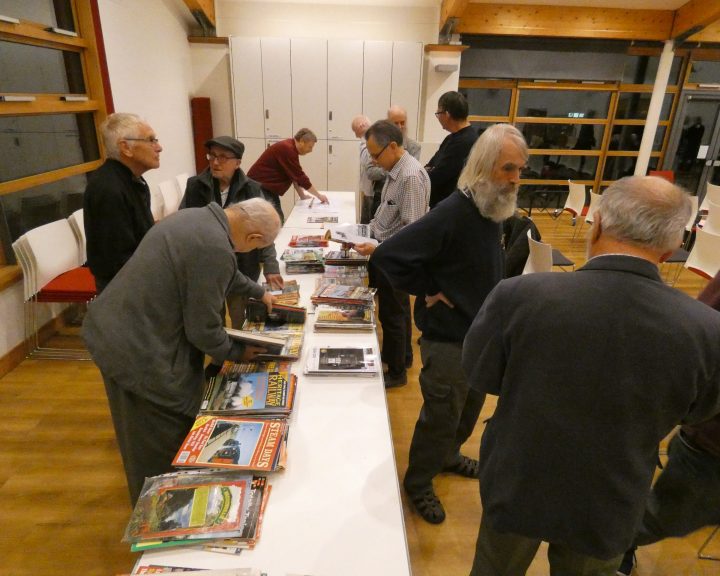

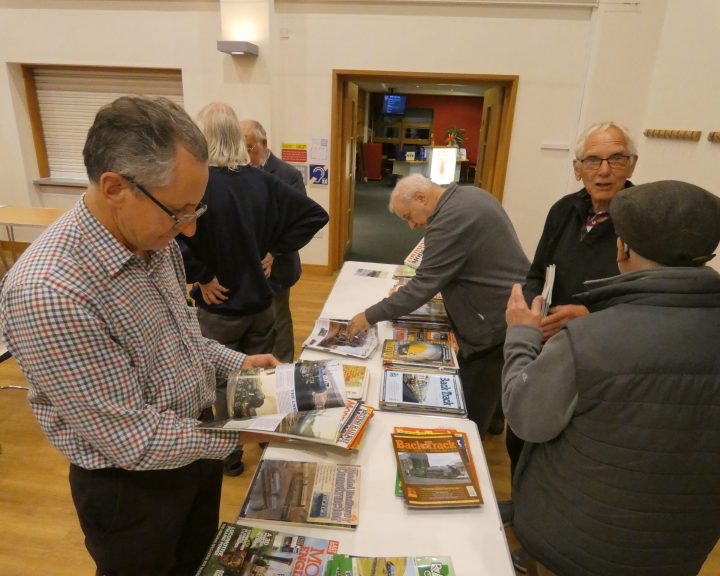

This club evening was the first after our long awaited return to the exhibition arena. Now our members wanted to talk about it and there was a good long response from the membership and this and other items will carry forward to the next committee meeting. Some good points were that we had at least 2 new members attending and the membership present for the evening had risen to 30. A bit more club business and then on to the main topic for the evening.

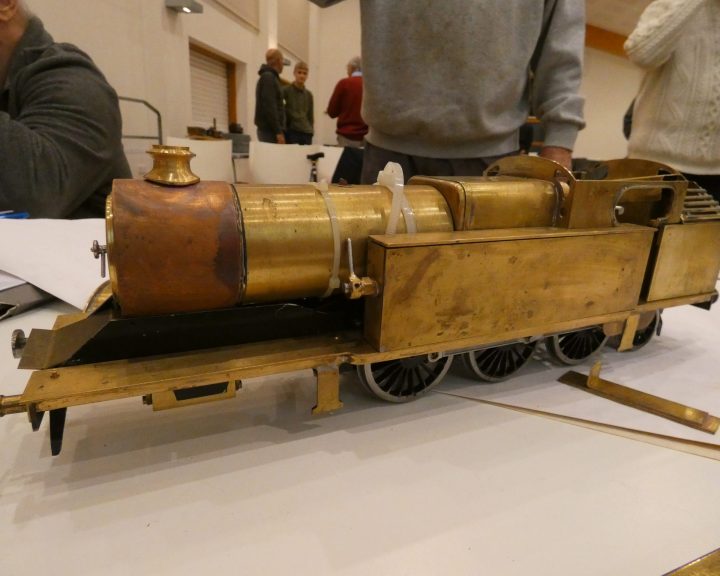

A good friend of the society Brian Looker, had agreed to share with us some of his building skills and experiences constructing live steam G1 locos. We had in front of us not one but 10 locomotives and this was a fraction of his locos either finished or in hand. Some were tank locos and others had a water and fuel tender.

Now Brian was a little reticent to stand in front of an audience and yours truly gave some moral support alongside him. I explained that the evening was unscripted and would go the way it would go! We went straight in with descriptions of boiler building and the finer points of steam production this immediately brought response from the members and the benefits of liquid fuel v gas were discussed. Our own steam buff Malcolm joined in with comments on the design of the boilers with boiler flues closely spaced but here it seems you can have too much heat as Brian explained.

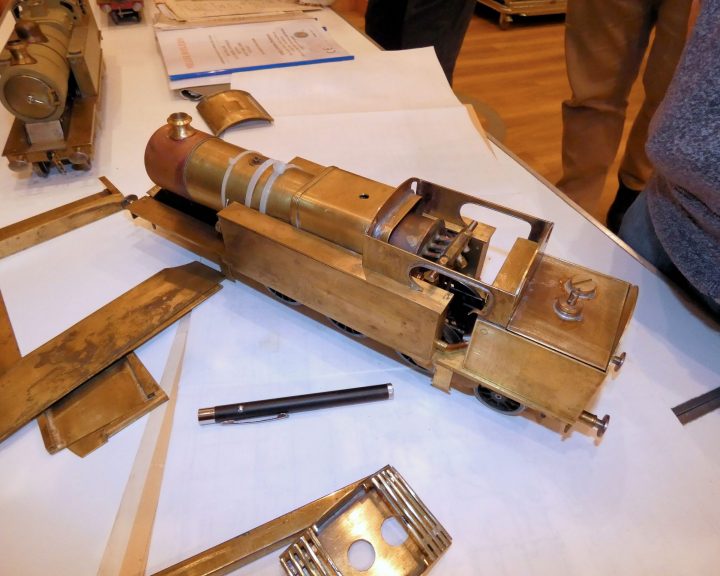

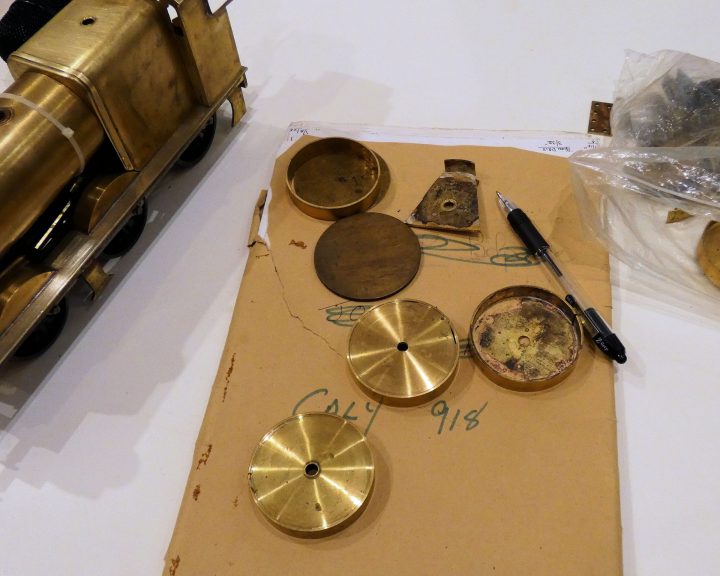

When initial points were resolved I dragged Brian back to basics of what he thought worth buying and what he constructed. Wheel splash covers were an example of the way he produced 3 similar items starting with a round band of brass supported by silver soldering a disc support and then machining to a good finish and then dividing into 3 parts.

Some items were more economical to buy in a finished state, like wheels, smoke box and further discussion revealed where to buy kits for these parts, and indeed whole locos. Brian now purchases ready-made boilers which come with a certificate detailing construction and initial pressure testing. Otherwise he liked to build from plans and the first reliable engine drawings and later kit produced was the "Project" which goes back many years, Powered by meths and later using Ecofuel the engine is very powerful and needs a train behind it to keep the speed down as a runaway is a very fast beast!

Now discussion moved to the chassis and the number of cylinders and Brian favours the double acting single cylinder mechanism all contained inside the chassis. Brian showed the jig which you can purchase when constructing the cylinder block, that positions all the holes in the right place. Then there is the two cylinder engine with inside valve gear and he showed another loco with the popular Walschaerts outside valve gear.

The 4-6-2 chassis had bogies but Brian said these are just attached to the chassis and non-weight supporting as the relatively heavy locos gave all the traction needed to haul a train, Brian had seen a similar engine pulling 14 coaches so quite a lot of power involved. I asked if he fitted spring suspension to the wheels but, no and then said that the axle bushes did have a little 'play' in them!

General construction was if it gets hot silver solder, otherwise soft solder was quite strong enough. The use of a gas jet for heat with soft soldering and with the aid of a 'pricker' to help the flow of the solder into the corners will create a good joint. Much of the soft soldering was in the tender and also the water and fuel containers. Achieving good square angle brass was talked about and Brian cuts down box section brass for this as it is more accurately formed. It is essential to clean up the brass first, wet and dry paper is good for this and leaves a slightly abraded surface to solder on to.

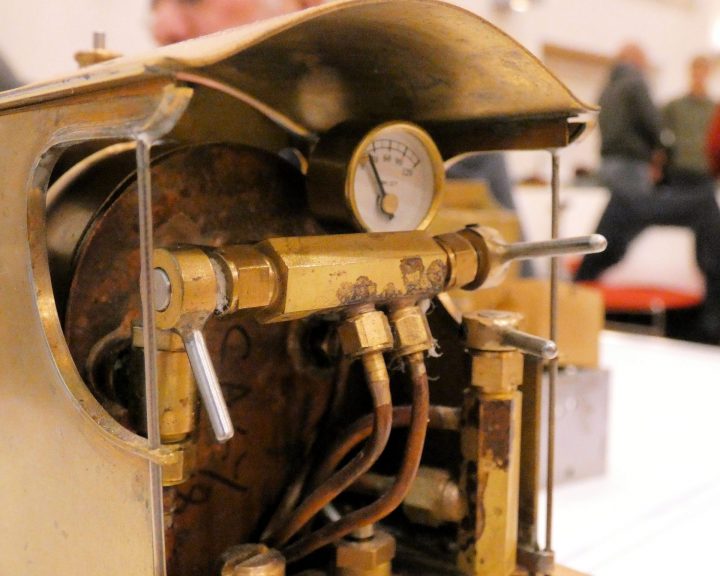

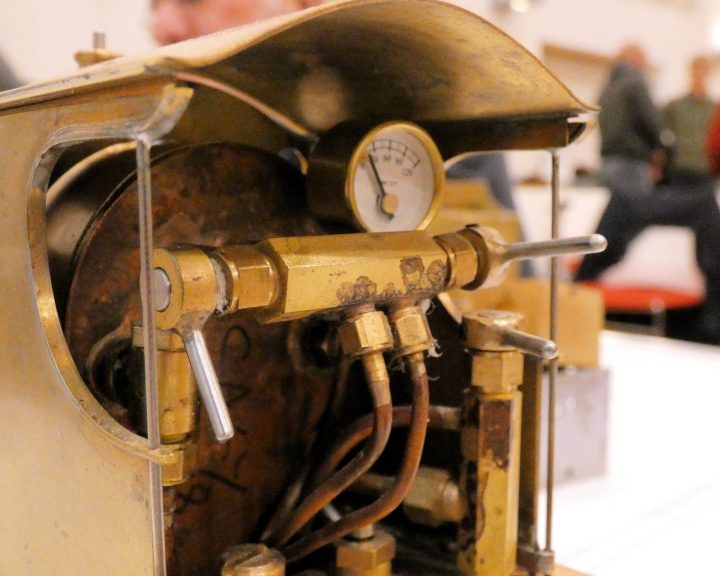

Getting water into the boiler had several options. He fitted two 'Clack' valves to the boiler and there was an internal axle pump which gives just a small amount of water each revolution, this was fed from the water tank. Then there was the start up fill of using a handheld pump to direct water straight into the boiler, again via the clack valve. Also there is a hand pump integral with the loco. The boiler is so small that a sight glass would be of little use however there is a pressure indicator and Brian said he runs to a maximum of 65 pounds but the engines easily run on less. Oil is slowly delivered directly to the valve gear and cylinder head where it is needed.

On top of the boiler is the pressure release valve and whistle and the then the smoke box chimney. This has to be positioned very accurately and Brian had a jig for this which ensured it is positioned correctly. The boiler is insulated with a ceramic wool fibre and the boiler cover is held in place by the boiler bands which need to be strong enough but not intrusive but also be able to be bolted through out of sight.

Testing was done on air with the expectation of forward and reverse running being good. Brian recommends the timing of steam admission to the cylinders as just after TDC Once that is done steaming up is an art on its own and Brian says he will come to us again when the light is better in the spring to discuss this and the safety aspects as well, perhaps before the start of a meeting but out in the open.

Having got everything working it is time to apply paint. The loco can be disassembled into component parts then using a toothbrush and Jiff/Cif cleaning product scrub away until it goes black and rinse in cold water. Then an etching primer is needed to give a good surface for the paint to adhere to. This should be given a week to dry off.

Painting can be achieved with special colours appropriate to the loco, these were once enamel but have now moved on to acrylic. Prepare the domestic oven by getting it to the lowest heat setting and turn off the heat, place the painted parts in the oven to bake onto the loco and leave for several hours.

Brian wound down the evening answering a few questions, one was what about radio control? Brian said that the way you ran a loco was to walk alongside checking it was moving well, water was getting into the boiler and generally working, then when OK you can let her run. There is not much room for R/C to control the throttle and it gets complicated to check steam pressure as well.

Brian received a very warm round of applause for an instructive and entertaining evening. At this point Brian turned to me and said, "I've never done that before" but he had a big smile on his face as he said it!

I had had minimal part in the evening, however our film director was dodging about and certainly earned his keep. Somewhere in the middle we had a tea break and as usual members were dragged away from conversations to return, thanks also to our refreshment team and of course the chair putter outers.

A full evening on model engineering, most enjoyable.

Roy Verden 14.10.22