Our Chairman opened the proceedings with a welcome and a big thank you for members who were part of the exhibition. Another successful one with similar visitor numbers as last year and a good amount of funds into the club.

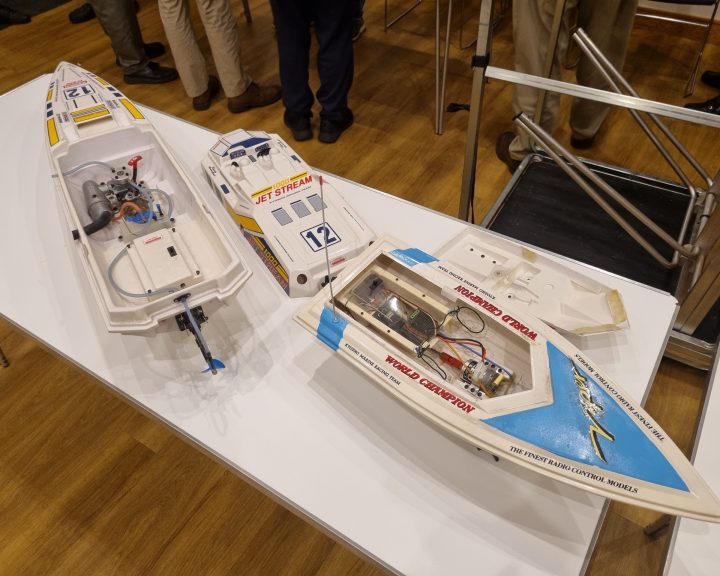

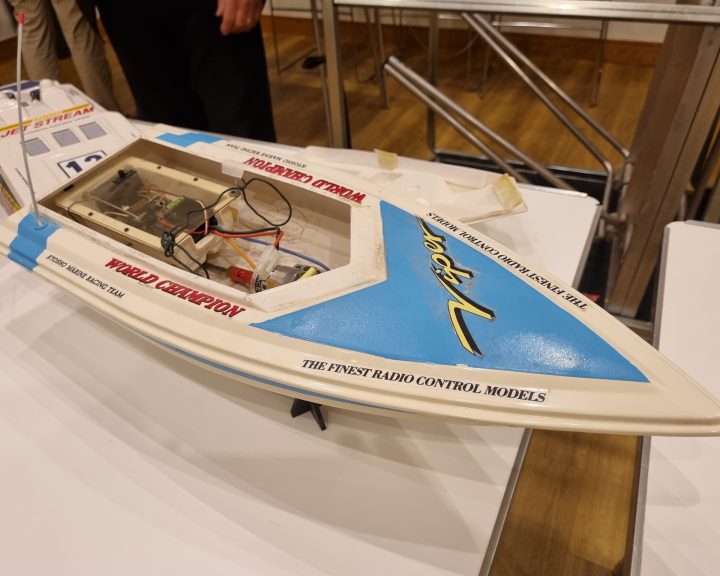

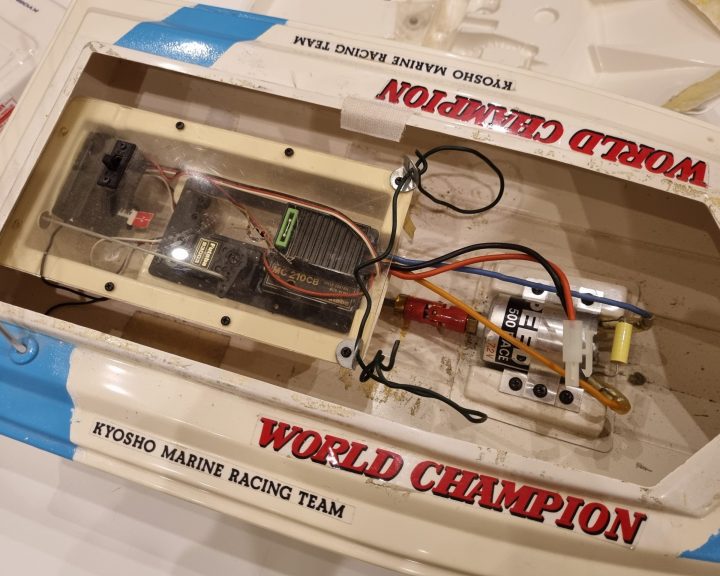

In the background we had a few members things going on, there were a couple of donated boats looking for new owners, a steam boat brought in to look at and a small lathe, I did not catch up with all of it but nice to see. Members are always welcome to bring in their models to either display or ask questions about further progress at all meetings.

Mike handed over to me and I introduced our speaker for the evening, Tony Ashgrove.

Tony had experience of replacing rifle barrels, that is for target shooting, and is also Chairman of the Hemel rifle club.

I thought this would be an interesting subject. Why you might ask? Well, I had been a competition shooter since I was 17 years old, Captain of an RAF station rifle team and then helped teach shooting to the local Sea Scouts. Then I joined the Dacorum rifle and pistol club, where I first met Mike Joseph. I ended up in the Herts. County rifle team for a couple of years until my eyesight became a problem.. So I was aware of the precision work that goes into a competition rifle. There are also 3 ex or current shooters in the audience.

Tony started off with the safety awareness necessary for all shooters and the handling of fire arms. Then he explained the details of a bullet and its cartridge, all carefully standardised so that they could be mass produced and fit any rifle. Tony mainly spoke about the competition equivalent of 7.62 diameter ammunition.

Now I had wondered how you can drill a hole through 30 inches of the barrel and come out in the right place, but decided this was a thought for others to worry about!

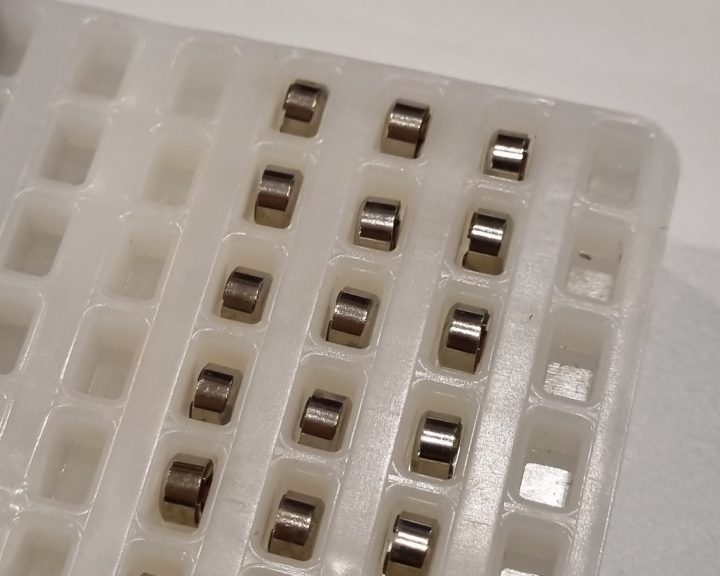

It was explained that the hole was the important part and the barrel was machined and also tapered in length around the hole! The stages of replacing a barrel were explained, at the moment they were importing the rifle barrels and then the fitting was done using a lathe and various cutting tools and gauges. Gauges in the shape of trial bullet shaped ones. Tony explained how tightly the rifle barrel is located into the mechanics of the firing mechanism holding the round of ammunition.

The barrel and stock had to feel as one when in use and Tony explained how this was done with a bedding compound and the screwing down of the barrel to the stock. The fore and rear sights had to be replaced in exactly the same positions to maintain the accuracy of fire. The barrel has several spiral grooves internally and these are for spinning the bullet to stabilise it in flight. Depending on requirements up to 100,000 rpm.

As Tony was involved with the replacement of rifle barrels he was able to show the process on the screen with many stills and some video. He went through the process of dismantling a rifle and then the lathe work and the final testing. Things have moved on since my days and all parts of the rifle mechanism had to have a serial number and the parts noted for each rifle.

The explanation of the speed and fall over distance and the speed of the bullet came up. Speed is around Mach 2.6, so faster than Concorde! But as was pointed out not for as long! The way long distance, 1000 yard electronic targets, were operated using the super-sonic sound waves of the bullet to position the shot. Also the upward angle the rifle needed to be to account for the drop of the bullet. Tony pointed out that at 1000 yards the bullet takes 5 seconds to arrive.

Bullets travel close to the speed of sound, .22 at slightly less and .303 at considerably more. The one thing to avoid is going through the speed of sound as the incurred shockwave will upset the bullet in its trajectory.

Tony had been answering questions all along and his well thought out talk extended a bit so we had a slightly later break than usual.

So during tea break our Chairman and I had a discussion about his (Chairman) follow up talk about progress on his tank. The club time available was not enough and it would be more useful to delay the talk on his tank until later. We thought that opening up a new question session for Tony and then a review of the exhibition would be a good filler. We resumed our seats and that is how the evening continued until our usual finishing time.

Many of our members have lathes and workshop equipment and to see the industrial use and some possibly new processes was interesting. All I spoke to had found the talk very informative and Tony is to be congratulated the way he was able to handle the questions and interruptions and meld them into his talk. After another round of applause we adjourned for the evening.

Thanks as always to those that make the evening work with putting out the seating etc and of course to Jack and Neil for providing the refreshments. I think it was maybe an unexpected evening for content but a very enjoyable one considering the seemingly endless questions and queries.

Our Chairman asked all to be aware of our impact on the neighbours and requested all to leave quietly.

Roy

13th October 2023